Table of Contents

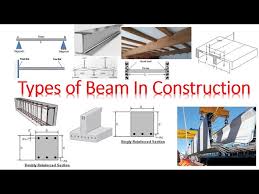

Toggle7 Different Types of Beams in Construction: Which One Is Right for Your Project?

Introduction

Beams are key components in construction that help support and distribute loads. Whether you’re working on a residential house, a commercial building, or a bridge, the type of beam you choose can impact the strength, stability, and overall appearance of your structure. This guide will walk you through seven different types of beams, explaining their unique characteristics, uses, pros, and cons. By the end, you’ll have a clearer idea of which beam is best suited for your project.

1. Simply Supported Beam

Characteristics:

- Support Mechanism: A simply supported beam rests on two supports at its ends. These supports let the beam pivot and move slightly. It’s the most straightforward type of beam, making it easy to understand and use.

- Materials: Commonly made from timber, steel, or reinforced concrete. The choice depends on the beam’s load and span.

- Load Distribution: When a load is placed on it, the beam bends downward. The highest stress occurs at the middle of the span, and the supports handle the load by transferring it to the foundation.

Common Uses:

- Homes: Often used for floor joists and roof beams, supporting upper levels and roofs.

- Bridges: Ideal for small bridges where simplicity and cost-effectiveness are important.

- Industrial Buildings: Suitable for simple roof structures or small-span supports.

Pros:

- Simple Design: Easy to construct and understand.

- Cost-Effective: Generally less expensive because of its straightforward design.

- Versatile: Can be used in many different types of buildings and structures.

Cons:

- Limited Span: Not ideal for very long spans without extra support.

- Deflection: Under heavy loads, it may bend significantly, requiring additional support.

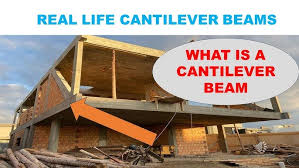

2. Cantilever Beam

Characteristics:

- Support Mechanism: A cantilever beam is fixed at one end and extends freely at the other. The free end is unsupported, which means it experiences higher stress and bending.

- Materials: Can be made from steel, reinforced concrete, or wood, depending on the project’s needs.

- Load Distribution: The load causes the beam to bend and create stress at the fixed end and the free end. The fixed support must handle this stress.

Common Uses:

- Balconies: Perfect for balconies that stick out from buildings, creating a clear space below.

- Bridges: Useful for sections of bridges that span gaps without needing support in the middle.

- Overhangs: Great for architectural features like awnings or projecting roofs.

Pros:

- Unobstructed Space: Provides clear space below the beam, ideal for architectural designs.

- Architectural Flexibility: Allows for unique designs and features.

- Minimal Support: Reduces the need for support columns below, which can enhance the structure’s look.

Cons:

- High Stress: The free end of the beam bears significant stress, requiring careful design.

- Complex Design: Needs precise calculations to ensure safety and performance.

3. Fixed Beam

Characteristics:

- Support Mechanism: Fixed beams are securely anchored at both ends, preventing rotation. A more stiff and sturdy structure is produced as a result.

- Materials: Typically made from steel or reinforced concrete to provide strength and rigidity.

- Load Distribution: Loads are spread more efficiently compared to simply supported beams, resulting in less deflection and higher load capacity.

Common Uses:

- Multi-Story Buildings: Supports floors in tall buildings, distributing loads across multiple levels.

- Heavy Machinery: Suitable for industrial applications needing strong support.

- Bridges: Used in bridges to enhance stability and load-bearing capacity.

Pros:

- Reduced Deflection: Experiences less bending under load, improving performance.

- Increased Load Capacity: Can support heavier loads than some other types of beams.

- Enhanced Stability: Provides greater stability due to the fixed support.

Cons:

- Complex Construction: Requires precise anchoring and design, making it more complicated to build.

- Cost: Generally more expensive due to the design and materials.

4. Continuous Beam

Characteristics:

- Support Mechanism: Continuous beams extend over three or more supports, creating a stable structure. They span multiple points, which helps distribute loads more evenly.

- Materials: Can be made from steel, concrete, or composite materials.

- Load Distribution: Loads are spread across multiple supports, reducing bending moments and enhancing efficiency.

Common Uses:

- Bridges: Ideal for multi-span bridges, distributing loads effectively.

- High-Rise Buildings: Supports large floor areas and multiple stories.

- Industrial Structures: Useful for large facilities requiring extensive support.

Pros:

- Reduced Bending Moments: Less bending stress compared to simpler beams.

- Efficient Load Distribution: Spreads loads more evenly, reducing strain on individual supports.

- Cost Savings: Potentially lowers material and construction costs.

Cons:

- Complex Design: Requires detailed analysis due to multiple supports.

- Construction Challenges: Precise placement and alignment of supports are necessary.

5. Overhanging Beam

Characteristics:

- Support Mechanism: An overhanging beam extends beyond one or both supports. The part that extends is unsupported by additional columns or walls.

- Materials: Constructed from steel, concrete, or wood.

- Load Distribution: The extended portion bears extra stress and bending, which requires careful design to maintain stability.

Common Uses:

- Balconies: Supports balconies that extend from a building.

- Architectural Features: Used for projecting roofs or canopies.

- Bridges: Creates sections that extend beyond supports for uninterrupted spans.

Pros:

- Versatile Design: Allows for creative architectural features and functional designs.

- Open Space: Eliminates the need for additional support below the beam.

- Aesthetic Attractiveness: May improve a building’s visual attractiveness.

Cons:

- Increased Stress: The extended part of the beam experiences higher stress, requiring careful engineering.

- Complex Analysis: Needs thorough structural analysis to ensure safety.

6. Trussed Beam

Characteristics:

- Support Mechanism: A trussed beam uses a series of triangles (trusses) to distribute loads. The triangular arrangement helps the beam handle large spans with less material.

- Materials: Often made from steel or wood, with modern applications sometimes using composites.

- Load Distribution: The truss design efficiently distributes loads through the beam, reducing stress on individual parts.

Common Uses:

- Roofs: Supports large spans in roof construction.

- Bridges: Used in bridge designs to span long distances.

- Towers and Pylons: Supports significant loads in structures like communication towers.

Pros:

- High Strength-to-Weight Ratio: Strong yet lightweight, making it ideal for long spans.

- Material Efficiency: Uses less material due to the efficient truss design.

- Versatility: Suitable for a variety of applications.

Cons:

- Complex Fabrication: Requires precise construction and assembly.

- Limited Aesthetics: May need additional design elements for visual appeal.

7.Composite Beam

Characteristics:

- Support Mechanism: Composite beams combine two different materials, typically steel and concrete, to take advantage of the strengths of both. The steel provides tensile strength, while the concrete offers compressive strength, making the beam robust and versatile.

- Materials: Usually composed of a steel beam with a concrete slab cast on top. The steel and concrete are connected through shear connectors to work together as a single unit.

- Load Distribution: The steel beam handles tensile stresses, while the concrete slab deals with compressive stresses. The combined action enhances load-bearing capacity and structural performance.

Common Uses:

- High-Rise Buildings: Ideal for multi-story buildings where strong, efficient load-bearing is required.

- Long-Span Bridges: Used in bridges to span long distances with enhanced load capacity.

- Industrial Structures: Suitable for large industrial buildings that need to support heavy loads and extensive spans.

Pros:

- High Strength: Offers superior strength and load-carrying capacity compared to individual materials alone.

- Efficient Use of Materials: Utilizes the strengths of both steel and concrete, often resulting in a more efficient design.

- Reduced Construction Time: Prefabricated steel elements and quick curing of concrete can speed up construction processes.

Cons:

- Complex Design: Requires careful design and coordination between materials to ensure proper interaction and load transfer.

- Higher Initial Costs: The combination of materials and need for precise fabrication can lead to higher initial costs compared to simpler beam types.

- Maintenance Needs: The steel components may need protection from corrosion, which can require additional maintenance.

How to Choose the Right Beam for Your Project

Selecting the right beam involves several factors:

- Load Requirements: Assess the type and amount of load the beam needs to support, including both static (dead) and dynamic (live) loads.

- Span Length: Measure the distance between supports to determine the appropriate beam span.

- Material Availability: Choose materials that are available and suitable for the project.

- Design Requirements: Ensure the beam type fits the architectural and structural design, including any aesthetic preferences.

- Environmental Conditions: Consider factors like moisture, temperature, and chemicals that might affect material performance.

- Construction Constraints: Evaluate construction methods and resources to ensure the beam type is practical.

Conclusion

Choosing the right beam is crucial for the success of your construction project. Each beam type—whether simply supported, cantilever, fixed, continuous, overhanging, trussed, or reinforced concrete—has unique features, advantages, and drawbacks. By evaluating factors such as load requirements, span length, material choices, design needs, environmental conditions, and construction constraints, you can make a well-informed decision that ensures the structural integrity and efficiency of your project.

FAQs

Q1: What is the most common type of beam used in residential construction?

Simply supported beams are the most common in residential construction due to their simplicity and cost-effectiveness. They give roofs and floors the vital support they need.

Q2: Can I use a cantilever beam for a balcony?

Yes, cantilever beams are perfect for balconies as they extend from the building without needing additional support below, creating an open space.

Q3: What materials are best for constructing beams?

The best material depends on the application:

- Steel: Offers high strength and flexibility.

- Concrete: Provides durability and fire resistance.

- Wood: Cost-effective for residential projects.

Q4: How do I determine the load-carrying capacity of a beam?

The load-carrying capacity is determined through structural analysis, considering material strength, beam dimensions, span length, and load conditions. Consulting a structural engineer ensures accurate calculations.

Q5: Can overhanging beams be used in bridge construction?

Yes, overhanging beams can be used in bridges to create sections that extend beyond supports, allowing for uninterrupted span.

If you want to get more knowledge about this so read more.

If you want more articles about Civil Engineering click on link.