How To Calculate Slab Thickness: 6 Steps Process with Essential Tips and Formulas

1. Understanding Slab Thickness and Its Importance

Slab Thickness Overview

Slab thickness is a crucial aspect of structural design, influencing the load-bearing capacity, deflection characteristics, and overall safety of the structure. It refers to the depth of a concrete slab, which serves as a floor, ceiling, or foundation element in buildings.

Importance of Correct Slab Thickness

- Structural Safety:

- Ensuring the slab thickness is adequate prevents structural failures such as bending, cracking, or collapse. A slab that’s too thin may not support the load adequately, while an overly thick slab may be unnecessarily expensive and heavy.

- Load-Bearing Capacity:

- The slab must support both live loads (e.g., people, furniture) and dead loads (e.g., the slab’s own weight and permanent fixtures). Correct thickness ensures that the slab can distribute these loads without excessive deformation.

- Durability:

- A correctly sized slab resists environmental factors such as temperature fluctuations, moisture, and chemical exposure. Proper thickness helps in mitigating issues like cracking and deterioration over time.

- Cost Efficiency:

- Optimizing slab thickness balances material costs and structural performance. Avoiding both over-thick and under-thick slabs helps in managing construction expenses while maintaining safety and functionality.

- Building Code Compliance:

- Adhering to minimum thickness requirements ensures that the slab meets local building regulations and safety standards, which is essential for obtaining permits and approvals.

2. Factors Influencing Slab Thickness Calculation

Load Considerations

- Dead Load (DL):

- Definition: Includes the self-weight of the slab and any permanently attached elements (e.g., walls, fixtures). The dead load is crucial for determining the slab’s basic thickness requirements.

- Calculation Example: For a slab with an initial thickness of 150 mm (0.15 m) and concrete density of 24 kN/m³:Dead Load=24 kN/m3×0.15 m=3.6 kN/m2\text{Dead Load} = 24 \text{ kN/m}^3 \times 0.15 \text{ m} = 3.6 \text{ kN/m}^2

- Live Load (LL):

- Definition: Refers to temporary or variable loads such as people, furniture, or equipment. Live loads can vary significantly based on the use of the building.

- Standard Values: Residential floors typically use 2-4 kN/m², while commercial spaces may require higher values (e.g., 5-10 kN/m²).

- Dynamic Loads:

- Definition: Includes loads that vary with time, such as vehicle traffic or machinery. These loads can impose additional stresses on the slab.

- Impact Consideration: May necessitate additional thickness or reinforcement to ensure stability and performance.

- Impact and Wind Loads:

- Considerations: For slabs exposed to external forces like wind or impact from moving objects, additional thickness or reinforcement may be required to withstand these forces.

Type of Slab (One-Way vs. Two-Way)

-

One-Way Slab:

- Description: Supported on two opposite sides, bending primarily in one direction. This type is often used in rectangular areas where the length is much greater than the width.

- Design Considerations: Load distribution is mainly along the shorter span, which influences the required thickness and reinforcement.

-

Two-Way Slab:

- Description: Supported on all four sides, bending in two directions. Suitable for more uniform or square areas where load distribution occurs in both directions.

- Design Considerations: Requires careful analysis of both spans for thickness and reinforcement, often necessitating more complex design calculations.

Material Properties

- Concrete Strength (f’c):

- Types: Concrete strength is measured in MPa (megapascals). Common grades include 20 MPa, 25 MPa, 30 MPa, and 40 MPa.

- Impact on Thickness: Higher-strength concrete allows for reduced thickness but may involve higher costs. Choose a grade that balances structural needs with cost considerations.

- Reinforcement:

- Types: Includes rebar (steel bars) or mesh, which are essential for handling tensile stresses and controlling cracking.

- Placement: Must adhere to design codes for minimum spacing and cover. Reinforcement should be placed in both directions for two-way slabs.

Environmental Conditions

- Climate Factors:

- Freeze-Thaw Cycles: In cold climates, thicker slabs or special concrete mixes (e.g., air-entrained concrete) may be required to resist freeze-thaw damage.

- Moisture: High humidity or exposure to water can necessitate additional waterproofing or thicker slabs to prevent deterioration.

- Soil Conditions:

- Bearing Capacity: Poor soil conditions may require thicker slabs or additional foundation work to distribute loads effectively and prevent settling.

Building Codes and Standards

- ACI 318 (American Concrete Institute):

- Guidelines: Provides comprehensive requirements for slab thickness, reinforcement, and load factors. Essential for ensuring compliance with safety and performance standards.

- Eurocode 2:

- Guidelines: Offers detailed provisions for concrete slab design, including thickness and reinforcement. It includes provisions for various load scenarios and environmental conditions.

- Local Building Codes:

- Requirements: Vary by region and must be reviewed to ensure that the slab design meets local regulatory requirements and safety standards.

3. Step-by-Step Process to Calculate Slab Thickness

Step 1: Determine the Type of Slab

- Identify the slab type: Based on span dimensions and load requirements. Decide if a one-way or two-way slab is more appropriate for your project.

- One-Way Slab: Suitable for rectangular spans where bending is predominantly in one direction.

- Two-Way Slab: Suitable for more evenly supported spans where bending occurs in both directions.

Step 2: Calculate Load Requirements

- Determine Dead Load:

- Calculate the self-weight of the slab and any permanent fixtures. Use the density of concrete and the initial thickness to find this value.

- Example Calculation: For a slab with a density of 24 kN/m³ and an initial thickness of 150 mm:Dead Load=24 kN/m3×0.15 m=3.6 kN/m2\text{Dead Load} = 24 \text{ kN/m}^3 \times 0.15 \text{ m} = 3.6 \text{ kN/m}^2

- Estimate Live Load:

- Refer to local building codes for standard live load values based on the slab’s intended use. Add this to the dead load to get the total load.

- Sum Up Dynamic Loads:

- Include additional stresses from moving loads, such as vehicles or machinery, if applicable. These can impact the thickness required for stability.

- Total Load Calculation:Total Load=Dead Load+Live Load+Dynamic Loads\text{Total Load} = \text{Dead Load} + \text{Live Load} + \text{Dynamic Loads}

- Ensure this value accounts for all load types that the slab will experience.

Step 3: Select Material Strength and Properties

- Choose Concrete Grade:

- Based on required strength and durability. Higher grades allow for reduced slab thickness but involve higher costs.

- Example Selection: For a residential slab, a grade of 25 MPa may be appropriate, while a commercial slab might require 30 MPa or higher.

- Determine Reinforcement:

- Choose appropriate rebar size and spacing based on the slab type and load requirements. Follow design codes for minimum reinforcement details.

Step 4: Use Relevant Design Codes and Standards

- Consult Design Codes:

- Apply guidelines from ACI 318, Eurocode 2, or local codes to determine minimum thickness and reinforcement requirements.

- Code Application: Ensure your design meets all specified limits for load-bearing capacity, deflection, and safety.

- Adjust for Code Requirements:

- Make necessary adjustments based on code requirements to ensure compliance. This may involve increasing thickness or adding reinforcement.

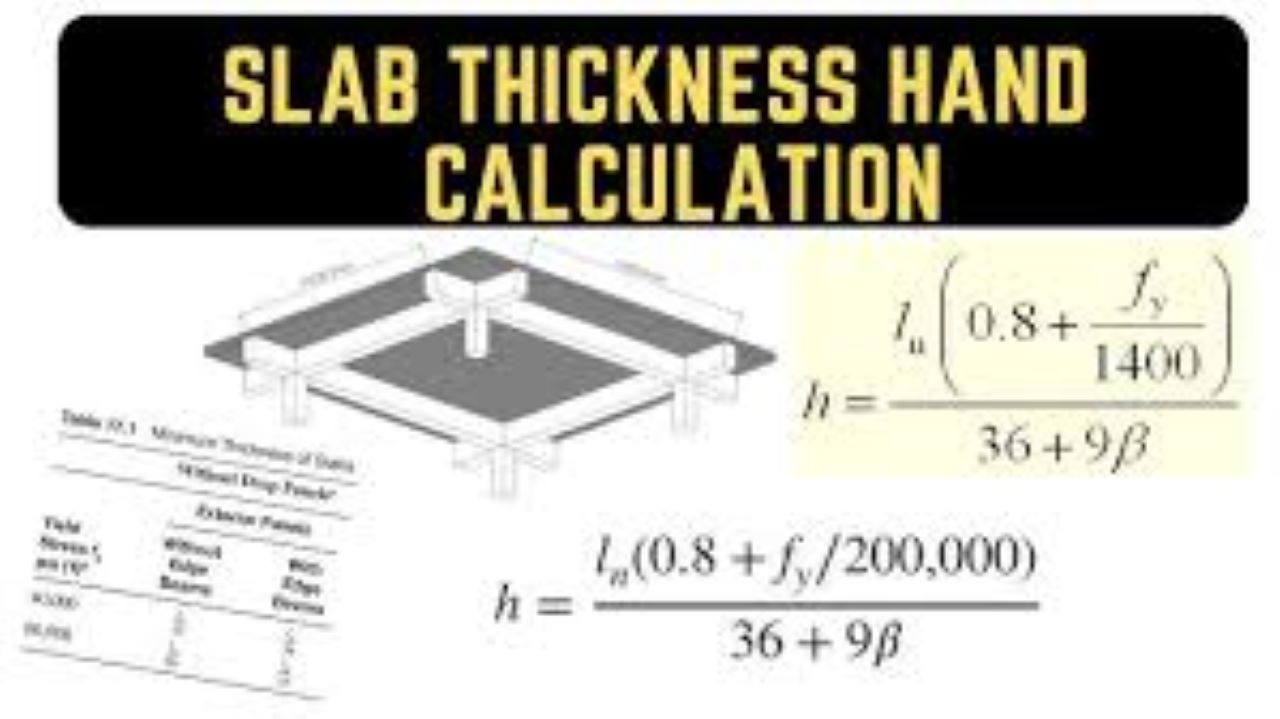

Step 5: Apply Slab Thickness Formulas

-

One-Way Slabs:

- Use the formula h=L20 to L30h = \frac{L}{20} \text{ to } \frac{L}{30}, where LL is the span length.

- Example Calculation: For a span of 6 meters:h=6000 mm20=300 mm (minimum)h = \frac{6000 \text{ mm}}{20} = 300 \text{ mm} \text{ (minimum)}

-

Two-Way Slabs:

- Use h=Lx35 to Lx40h = \frac{L_x}{35} \text{ to } \frac{L_x}{40}, where LxL_x is the shorter span length.

- Example Calculation: For a shorter span of 5 meters:h=5000 mm35=143 mm (minimum)h = \frac{5000 \text{ mm}}{35} = 143 \text{ mm} \text{ (minimum)}

-

Adjust for Additional Factors:

- Consider factors such as deflection limits, reinforcement, and environmental conditions to finalize the slab thickness.

4. Essential Tips for Accurate Slab Thickness Calculation

- Double-Check Load Assumptions:

- Verify load calculations to avoid errors in slab thickness. Accurate load assessment is crucial for structural safety.

- Account for Long-Term Effects:

- Include factors like creep (long-term deformation) and shrinkage in your calculations. These effects can impact the slab’s performance over time.

- Use Advanced Design Software:

- Tools like ETABS, SAFE, and STAAD provide precise calculations and handle complex designs, ensuring accuracy and efficiency.

- Consider Construction Tolerances:

- Allow for variations in material properties and construction practices. This ensures the slab performs as expected despite minor deviations.

- Ensure Deflection Control:

- Verify that the slab thickness limits deflection within acceptable levels as per design codes. Excessive deflection can affect structural performance and comfort.

5. Common Mistakes to Avoid

- Neglecting Building Codes:

- Always adhere to the latest codes and standards to ensure safety and compliance. Ignoring code requirements can lead to structural issues and legal problems.

- Underestimating Loads:

- Accurate load assumptions are essential. Incorrect load estimations can lead to inadequate slab thickness and potential structural failures.

- Ignoring Environmental Impact:

- Consider environmental conditions such as moisture and temperature. Adjust slab thickness and reinforcement to account for these factors.

- Incorrect Slab Type Selection:

- Choose the appropriate slab type based on span dimensions and load requirements. An incorrect choice can lead to design inefficiencies and safety concerns.

- Overlooking Deflection and Crack Control:

- Ensure the slab thickness meets deflection limits and includes proper reinforcement to control cracking. This helps maintain structural integrity and aesthetics.

6. Practical Examples of Slab Thickness Calculations

Example 1: One-Way Slab Calculation

- Scenario: A residential building with a 6-meter span and a total load of 10 kN/m².

- Minimum Thickness Calculation:h=L20=6000 mm20=300 mmh = \frac{L}{20} = \frac{6000 \text{ mm}}{20} = 300 \text{ mm}

- Revised Thickness: Consider 300 mm as a starting point. Adjust based on deflection limits and reinforcement requirements.

Example 2: Two-Way Slab Calculation

- Scenario: A commercial building with a 5-meter shorter span and a total load of 12 kN/m².

- Minimum Thickness Calculation:h=Lx35=5000 mm35=143 mm (minimum)h = \frac{L_x}{35} = \frac{5000 \text{ mm}}{35} = 143 \text{ mm} \text{ (minimum)}

- Revised Thickness: Choose a practical thickness of 150 mm, ensuring compliance with deflection and reinforcement requirements.

7. FAQs About Slab Thickness Calculation

- What is the minimum slab thickness for residential floors?

- Answer: Typically, 100-150 mm is used for residential floors, depending on load requirements and span lengths. Refer to local codes for specific requirements.

- How do environmental conditions affect slab thickness?

- Answer: Extreme conditions such as freeze-thaw cycles or high moisture may require thicker slabs or special mixes to prevent damage.

- Can I use lightweight concrete for slabs?

- Answer: Yes, lightweight concrete can be used, but adjust thickness and reinforcement based on its properties to ensure strength and load capacity.

- How does slab thickness affect cost?

- Answer: Thicker slabs increase material costs but can reduce maintenance needs and structural risks. Proper thickness balances cost and performance.

- What tools can I use for slab thickness calculation?

- Answer: Software like ETABS, SAFE, and STAAD offer precise calculations for slab design, handling complex scenarios and ensuring accuracy.

- Is reinforcement necessary for all slabs?

- Answer: Yes, reinforcement is essential for handling tensile stresses and preventing cracking. Follow design codes for reinforcement requirements.

- How do I handle irregular slab shapes in calculations?

- Answer: Break down irregular shapes into simpler sections or use advanced modeling software for accurate analysis and design.

- What are the consequences of an overly thick slab?

- Answer: While it increases strength, an overly thick slab may result in higher costs and additional weight that can impact the foundation.

- How do slab thickness and deflection relate?

- Answer: Thicker slabs generally reduce deflection, improving structural performance and occupant comfort. Ensure thickness limits deflection as per design codes.

- Can slab thickness affect building insulation?

- Answer: Yes, thicker slabs provide better thermal mass, which can influence insulation requirements and energy efficiency.

8. Conclusion

Calculating the correct slab thickness is essential for structural safety, durability, and cost efficiency. By following a detailed, step-by-step process and considering all relevant factors, you can design a slab that meets performance requirements and adheres to building codes.

This guide provides an in-depth look at the factors affecting slab thickness, the calculation process, and practical examples to help you make informed decisions. Whether you’re a structural engineer or a DIY builder, understanding these principles ensures that your slab design will be both effective and compliant.

If you have any questions or need further clarification on slab thickness calculations, feel free to reach out for additional guidance and support.

If you want to get more knowledge about this so read more.

If you want more articles about Civil Engineering click on link.