Top 10 Benefits of Using RCC in Modern Buildings

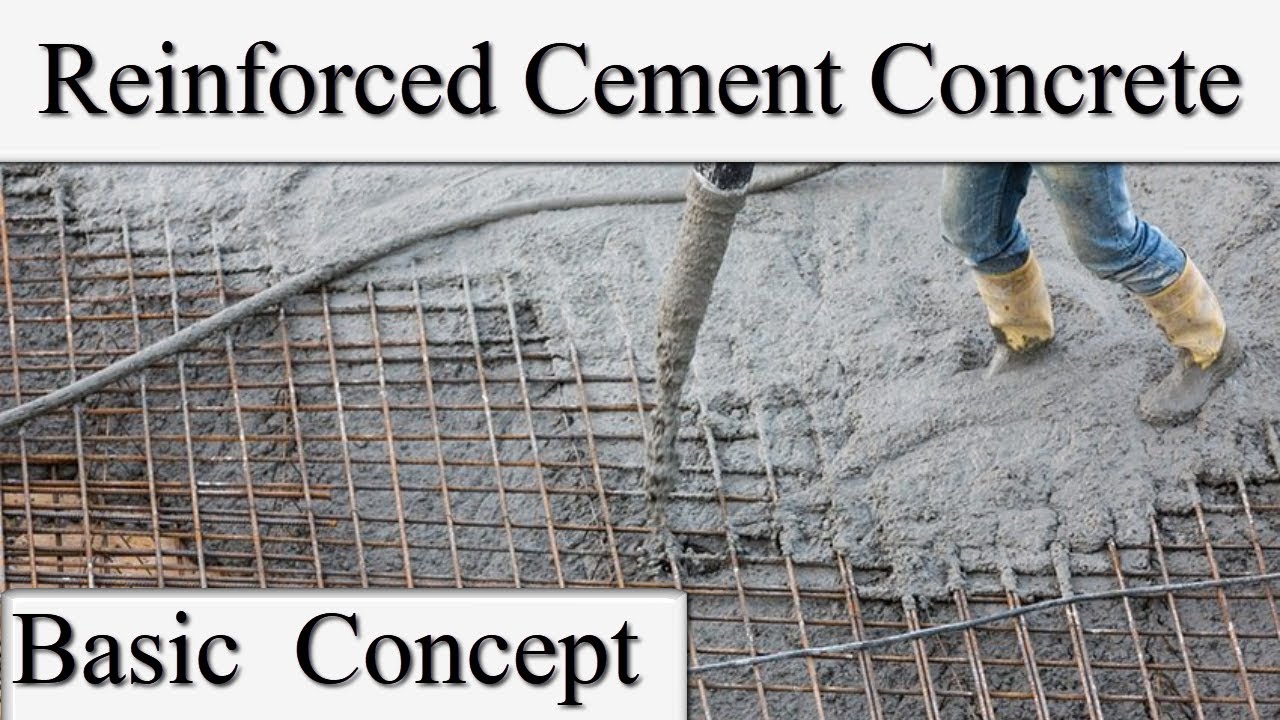

Explore the top 10 benefits of using RCC in modern buildings demonstrating why it remains the preferred choice for engineers, architects, and builders. Reinforced Cement Concrete (RCC) has become the cornerstone of modern Buildings, revolutionizing how we build durable, efficient, and sustainable structures. With its blend of concrete’s compressive strength and steel’s tensile strength, RCC offers unmatched performance in a wide range of applications.

Reinforced Cement Concrete (RCC):

1. Enhanced Strength and Durability

1.1 High Load-Bearing Capacity

RCC structures are known for their exceptional strength, which makes them capable of supporting substantial loads. The combination of concrete’s compressive strength and steel’s tensile strength provides a robust framework that can handle the stresses and strains of various construction applications.

Applications: RCC is ideal for high-rise buildings, bridges, and industrial structures where load-bearing capacity is crucial. The strength of RCC also allows for longer spans and more flexible design options.

1.2 Resistance to Environmental Factors

RCC is highly durable and resistant to environmental factors such as moisture, temperature variations, and chemical exposure. This resistance helps extend the lifespan of structures and reduces maintenance costs over time.

Examples: RCC is widely used in coastal and industrial environments where exposure to harsh conditions is common. The concrete mix can be customized with additives to enhance its resistance to specific environmental challenges.

2. Flexibility in Design and Construction – Benefits of RCC

2.1 Versatile Applications

RCC offers great flexibility in design, allowing for the creation of complex shapes and structures. Whether it’s for residential, commercial, or industrial projects, RCC can accommodate various architectural styles and requirements.

Innovations: Modern construction techniques, such as formwork systems and 3D modeling, enable the precise execution of intricate RCC designs, including curved surfaces and irregular geometries.

2.2 Adaptability to Different Construction Techniques

RCC can be utilized with various construction methods, including precast, cast-in-situ, and modular construction. This adaptability allows builders to choose the most efficient and cost-effective technique for their specific project.

Techniques: Precast RCC elements can be manufactured off-site and assembled on-site, reducing construction time and improving quality control.

3. Cost-Effectiveness

3.1 Economical Material Costs

While the initial cost of RCC construction may be higher compared to some alternatives, the long-term cost benefits outweigh the initial investment. RCC’s durability reduces the need for frequent repairs and replacements, leading to significant savings over the life of the structure.

Cost Analysis: RCC’s longevity and low maintenance requirements contribute to its overall cost-effectiveness, making it a preferred choice for large-scale projects.

3.2 Reduced Labor Costs

RCC construction often involves fewer labor-intensive processes compared to traditional construction methods. The use of modern construction technologies and techniques helps streamline the construction process, reducing labor costs and project timelines.

Efficiency: The use of automated machinery and prefabricated elements in RCC construction can further minimize labor requirements and enhance efficiency.

4. Improved Fire Resistance

4.1 High Fire-Resistant Properties

RCC is known for its excellent fire-resistant properties, making it a safe choice for building structures. Concrete’s ability to withstand high temperatures without losing strength or integrity contributes to enhanced fire safety.

Standards: RCC structures are designed to meet stringent fire safety codes and standards, ensuring that buildings remain safe during fire emergencies.

4.2 Fireproofing Techniques

Additional fireproofing measures, such as applying fire-resistant coatings and using fire-rated formwork, can further enhance RCC’s fire-resistant capabilities.

Examples: High-rise buildings and commercial complexes benefit from RCC’s fire resistance, providing added safety for occupants and reducing fire damage.

5. Sustainability and Environmental Benefits – Benefits of RCC

5.1 Energy Efficiency

RCC structures contribute to energy efficiency by providing good thermal mass, which helps regulate indoor temperatures. The high thermal mass of concrete helps to reduce the need for heating and cooling, leading to lower energy consumption.

Green Building: Incorporating RCC into green building practices supports sustainability goals and can contribute to achieving certifications such as LEED (Leadership in Energy and Environmental Design).

5.2 Recyclability and Low Environmental Impact

Concrete is made from abundant natural materials, and its production can be optimized to reduce environmental impact. Additionally, RCC elements can be recycled or repurposed at the end of their lifecycle.

Sustainable Practices: Using recycled aggregates and incorporating supplementary cementitious materials (SCMs) can further enhance the environmental sustainability of RCC construction.

6. Low Maintenance Requirements

6.1 Minimal Maintenance Needs

RCC structures typically require minimal maintenance due to their durability and resistance to weathering and wear. This low-maintenance characteristic reduces the need for frequent repairs and replacements.

Benefits: Long-term savings are achieved through reduced maintenance costs, which can be significant in large-scale construction projects.

6.2 Ease of Repair

In the event of damage, RCC structures are relatively easy to repair. The repair process often involves applying surface treatments or reinforcing affected areas, which can be done efficiently.

Techniques: Advanced repair techniques, such as epoxy injections and surface patching, help restore the integrity of RCC structures.

7. Enhanced Safety and Stability – Benefits of RCC

7.1 Structural Stability

RCC provides excellent structural stability due to its strength and rigidity. This stability is essential for withstanding external forces, such as wind, seismic activity, and load variations.

Design Considerations: Engineers can design RCC structures to meet safety standards and resist dynamic loads, ensuring the safety of occupants and the longevity of the building.

7.2 Seismic Resistance

RCC can be designed with seismic-resistant features, such as reinforced elements and flexible joints, to improve the structure’s ability to withstand earthquakes.

Examples: In earthquake-prone regions, RCC is often used in conjunction with seismic design principles to enhance the safety and resilience of buildings.

8. Enhanced Aesthetic Appeal

8.1 Design Flexibility for Aesthetics

RCC allows for a wide range of architectural finishes and treatments, from smooth surfaces to textured or patterned finishes. This design flexibility enables architects to achieve their desired aesthetic effects.

Techniques: Decorative techniques, such as exposed aggregate finishes and colored concrete, can enhance the visual appeal of RCC structures.

8.2 Integration with Other Materials

RCC can be seamlessly integrated with other materials, such as glass, steel, and wood, to create visually striking and functional designs.

Examples: Modern architectural projects often use RCC in combination with other materials to achieve innovative and aesthetically pleasing designs.

9. Efficient Construction Process

9.1 Fast Construction Techniques

Modern RCC construction techniques, such as precasting and modular construction, can significantly reduce construction time. Prefabricated RCC elements are manufactured off-site and assembled quickly on-site, accelerating project completion.

Benefits: Faster construction timelines lead to reduced project costs and earlier occupancy, making RCC an attractive option for time-sensitive projects.

9.2 Streamlined Project Management

The use of RCC simplifies project management by providing a reliable and consistent construction method. The standardized nature of RCC construction helps ensure quality control and efficient project execution.

Management Tools: Advanced project management tools and technologies facilitate the planning, coordination, and execution of RCC construction projects.

10. Versatility in Application

10.1 Wide Range of Applications

RCC is versatile and can be used in various construction applications, including residential, commercial, industrial, and infrastructural projects. Its adaptability makes it suitable for a broad spectrum of construction needs.

Applications: Common uses of RCC include high-rise buildings, bridges, dams, pavements, and retaining walls.

10.2 Adaptability to Different Project Scales

RCC can be scaled to suit projects of different sizes and complexities, from small residential buildings to large-scale infrastructure projects.

Examples: Whether for a small home or a large bridge, RCC provides the flexibility to meet diverse construction requirements.

Conclusion

Reinforced Cement Concrete (RCC) offers numerous benefits that make it a preferred choice for modern construction projects. Its strength, durability, cost-effectiveness, and versatility make it suitable for a wide range of applications, from residential buildings to large-scale infrastructure. By leveraging RCC’s advantages, builders and architects can create safe, sustainable, and aesthetically pleasing structures that stand the test of time.

Understanding and utilizing the benefits of RCC can lead to more efficient construction processes, reduced long-term costs, and enhanced structural performance. Whether you are involved in designing, planning, or building, RCC provides a reliable solution to meet the demands of contemporary construction.

If you want to get more knowledge about this so read more.

If you want more articles about Civil Engineering click on link.